What is Hot Weather Concreting

Natural elements, particularly outrageous weather patterns, influence substantial quality and properties. Sweltering weather conditions makes difficulties, and the impact is something other than the course of events. There will be antagonistic ramifications for the task in the event that proper measures aren’t attempted.

At the point when cement is blended, shipped, and poured in the raised temperature, under low dampness, and under sun powered radiation, or wind, it is named warm weather conditions cementing. This might prompt corruption of the characteristics of solidified concrete by speedy water misfortune or concrete hydrations where insurances are to be conceived.

Sweltering weather conditions combined with dampness and wind assumes a crucial part in influencing the periods of substantial creation and situation processes. They influence the general strength and toughness of cement. Concrete blended, put, and relieved at increased temperatures prompts before qualities than that created and restored at lower temperatures.

Impact of Hot Climate Concreting

Outcome of blistering weather conditions cementing activity by and large depended on the actions taken to facilitate the concrete hydration responses inside concrete and limit the pace of dampness vanishing from newly blended concrete. Be that as it may, here are a portion of the potential disadvantages brought about by sweltering climate:

- Elevated water demand

- More slump loss

- Increased setting rate

- High tendency for plastic-shrinkage cracking

- Increased risk of dry shrinkage and thermal cracking

- Reduced 28-day and later strengths

- Better tendency for differential thermal cracking

- Tendency for differential thermal cracking

- Increased variability in surface appearance

- Enhanced permeability

Best Practices for Hot Weather Concreting

It is ideal to adjust quality, expenses, and accessibility of assets for blistering weather conditions cementing. While it is unreasonable to expect weather patterns and restoring conduct, steady checking of the temperature and strength is basic to guarantee productive relieving and different measures. The following are key tips for each period of the substantial interaction.

Planning

It is critical to foreknow, plan, and direction in the underlying periods of substantial assembling process for progress under warm circumstances. Start by understanding the dampness levels on the venture site while projecting and relieving the substantial. It is fundamental to ponder the best hours to pour the substantial, anticipated temperature, and whether it will be gainful to pour and complete the substantial that very day thinking about the normal temperature.

Batching and Mixing

After learning the anticipated weather conditions on site, the concrete mix design can assist in lowering the associated risk involved with hot weather concreting. Here are some of the aspects to take care of while batching and mixing.

- Reduce the cement content

- Add mineral admixtures

- Use Plasticizers

- Reduce concrete temperature

- Minimize transport time

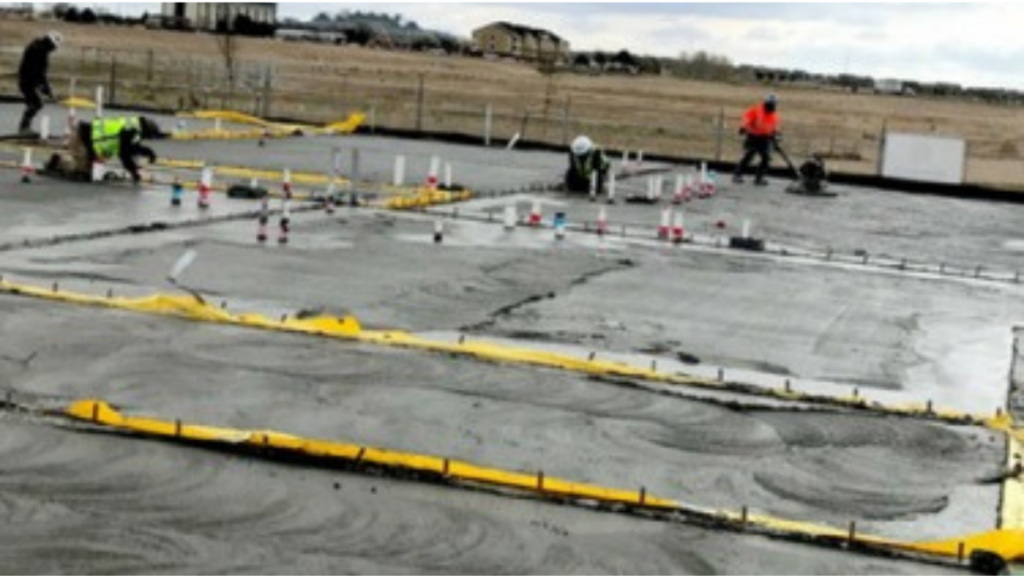

Placing and Finishing

Warm weather conditions may lead to a risen moisture evaporating rate and reduced setting time, thereby resulting in the concrete mix being solidified quickly and hard to handle. Hence, the duration to place, finish, and cure concrete will be lower than normal circumstances. To circumvent elevated temperatures that can negatively affect concrete strength, shift the pouring time to late night or early morning. This may lead to concrete being cured for some time without the dominance of hot temperatures. It is important to connect with the batching plant and subcontractors well.

Curing

The main motive behind the entire curing phase is to assure that the cement hydration process achieves the maximum strength potential of the concrete mix. Moisture loss and extreme temperatures are the two most important things to be avoided.

The number of the above-mentioned tips to be taken depends on the type of construction, the temperature of the ambient air, low relative humidity, wind speed, concrete temperature, and others. A few or all the above precautions will be taken at a time based on neediness.

It is essential to have sufficient provisions for labor and placement equipment to minimize time required for placing and finishing the concrete rapidly. With the proper precautions it will be possible to control the effects of hot weather when placing and finishing concrete jobs to a high quality.